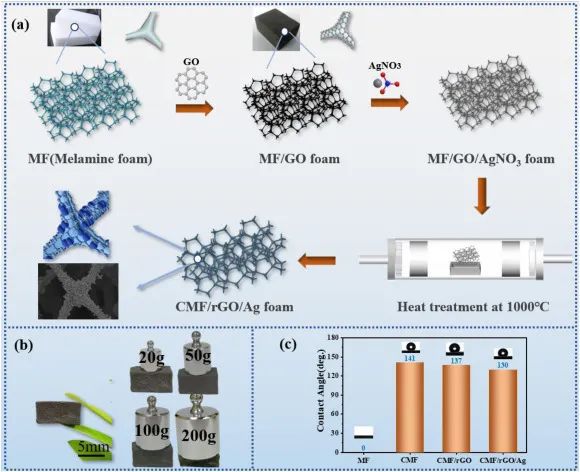

Recently, Sun Rong and other related researchers from the Shenzhen Institute of Advanced Technology, Chinese Academy of Sciences proposed a simple one-step heat treatment strategy to prepare lightweight silver/reduced graphene oxide coated carbonized melamine (CMF/rGO/Ag) foam materials. The carbonized-composite melamine foam material provided excellent mechanical properties and excellent EMI shielding effect (EMI SE).

The rise of 5G communications and smart phones has exacerbated the problem of electromagnetic interference.

Severe electromagnetic interference can cause data loss, system failure, and even endanger human health.

The development of high-performance electromagnetic interference shielding materials with ultra-low density and good mechanical flexibility is an effective way to suppress harmful electromagnetic wave pollution or radiation.

For traditional metal materials, improving conductivity has always been the primary strategy for achieving high-performance shielding materials.

In addition, new nanomaterials such as graphene, carbon nanotubes, and MXene have also been reported to have high EMI shielding performance.

Due to the highly flexible manufacturing process of nanomaterials, these materials are processed into foam or film form for EMI shielding. Compared with the foamed form of nanomaterials, dense films exhibit higher conductivity.

High conductivity can directly generate high EMI SE by strongly reflecting incident electromagnetic waves.

For example, the electromagnetic wave reflection coefficient of highly conductive metals usually exceeds 90%, which means that 90% of incident electromagnetic waves will be reflected into free space.

The reflected electromagnetic waves can also cause serious secondary electromagnetic radiation pollution. It is still a challenge to obtain high-performance EMI shielding materials with low electromagnetic wave reflection coefficient.

The foam-type shielding material is composed of a porous structure. Due to its light weight, good mechanical compressibility and adjustable EMI shielding performance, it has great potential in replacing traditional rigid metal shielding materials.

In particular, the porous structure enables the foam-type shielding material to have obvious multiple reflections on incident electromagnetic waves, so that the foam can absorb and attenuate electromagnetic waves. It has been reported that the porous structure will enhance the absorption of electromagnetic waves by MXene.

Compared with solid materials, the porous structure has better electromagnetic wave impedance matching ability, and can make incident electromagnetic waves enter the internal structure of the shielding foam. Therefore, EMI shielding materials with low reflection coefficient and high absorption coefficient should have good impedance matching (low reflection) and high multiple reflection. For example, layered structures, multi-layer structures and isotropic structures have been prepared, with high EMI SE and absorption coefficients. Generally speaking, complex structures and multi-components often involve multi-step processing, and mechanical flexibility is poor.

The silver-plated polyimide foam was prepared by physical spraying method, and its density was 23kg/m3. The silver-plated melamine foam was prepared by chemical deposition. The prepared silver-plated melamine foam has an EMI high SE of 90 dB and a silver content of 63.5 wt%. In addition, a copper/nickel coated polymethacrylimide hybrid foam and gold nanoparticle coated polymer-based nanofiber electromagnetic interference shielding electroless plating method is also proposed.

However, due to the inherent interface mismatch between the rigid metal and the flexible frame, the metal foam shielding materials prepared by electroplating, electroless plating and physical spraying have poor mechanical properties. Enhancing the connection between the metal particles and the flexible foam skeleton and realizing metal foam shielding materials with excellent mechanical properties are still full of challenges.

In this study, the author proposed a simple one-step heat treatment strategy to prepare lightweight silver/reduced graphene oxide coated carbonized melamine (CMF/rGO/Ag) composite foam material, which has excellent mechanical properties and Excellent EMI shielding effect (EMI SE). Due to the enhanced interface between the composite framework and the silver, the CMF/rGO/Ag foam showed excellent structural stability after 1000 loading-unloading compression test cycles. In addition, the EMI SE of the foam reached 50.6 dB at a density of only 16 mg cm2 g-1 and an ultra-low Ag content of 0.09 vol%.

Interestingly, the cooperation of the porous framework and multiple interfaces resulted in the unusually high absorption coefficient (over 0.5) of the CMF/rGO/Ag foam. The high absorption coefficient shielding mechanism of CMF/rGO/Ag foam was further studied by finite element analysis (FEA). The excellent near-field EMI shielding performance of CMF/rGO/Ag foam shows that low-density, strong CMF/rGO/Ag foam has great advantages and broad application prospects as EMI shielding materials for electronic packaging.